How To Build A Rolling Set Wall

Sabbatum Morning Workshop: How To Build a Sliding Pegboard Storage System

This projection takes workshop storage to a whole new level, employing both sides of seven pieces of pegboard, all housed inside a compact box. Watch the video to run into how it's made.

![]() Time

Time

An hour or less

![]() Complexity

Complexity

Beginner

![]() Price

Price

$51–100

Introduction

If you've got a couple of hours to hang out in your shop on Saturday forenoon, you tin can build this brilliant pegboard storage system. Check out the step-by-step photos, instructions, tech art and a how-to video below!

Tools Required

Materials Required

- 2'x4' 1/two" Plywood (iii)

- 2'x4' i/four" Pegboard (4)

- 8' 1x3 Boards (4)

For the most part, we but utilise pegboard in one mode: past tacking it to a wall and having 1 of the sides available for hanging upward tools. This Saturday Morning Workshop shows you how to brand use of both sides of whatever size piece of pegboard. Plus, this blueprint is completely flexible and can exist sized to fit your needs.

Because this sliding storage organisation will concord many heavy tools, you must mount it on sturdy shelving. Not shaky, store-bought shelving, but the sturdy, stock-still-in-place, floor-to-ceiling shelves yous've either already congenital (or have thought about building) in your workshop. You lot can also mountain this organization directly to some studs. (Make sure to use iii or four studs and three or 4 screws in each stud in lodge for this mega-toolbox to be secure on your wall).

Associates takes just a couple of hours with only a round saw, a miter saw, an 18-guess brad nailer and a drill. Materials are bachelor at whatever dwelling house centre. Use 1/4-in. tempered pegboard for durability (i/8-in. is also wimpy).

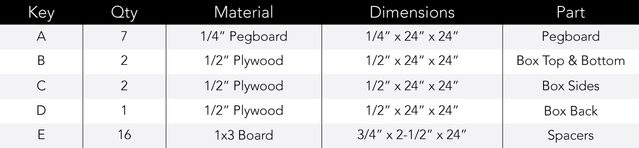

Cutting List

Project Plans

Project step-past-stride (seven)

Step 1

Create the Outer Box

Utilise a circular saw to crosscut the ane/two-in. plywood into five 24-in. x 24-in. pieces. The procedure we used was to brand an "H" using wood-topped sawhorses, set up a guide and brand the cutting through the stacked plywood pieces. Brand sure to factor in your circular saw's base of operations plate when measuring where to put the guide. Glue and smash the sides of the box to the top and lesser pieces.

Step 2

Cut the Pegboard

Cut the pegboard into 24-in. x 24-in. pieces using the same method as to a higher place with saw horses and a circular saw.

Pace 3

Brand & Attach the Spacers

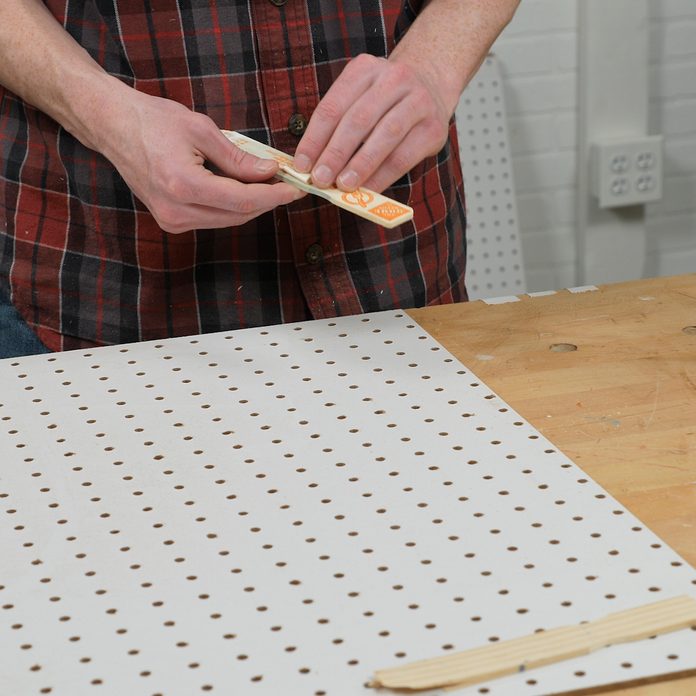

Nosotros used paint sticks for our spacers, but some cardboard or any other 1/8-in.-thick material volition work just fine. Tape the spacers to the four corners of ane of the pegboard pieces. This added width is to allow for play in the grooves of the storage system. This first piece of pegboard will be used to space all of the groves inside the box.

Step iv

Cutting 1x3 Boards to Length

Use a miter saw to measure out, marking and cut all of the 1x3s into 24-in. pieces. Clench a scrap piece to your workbench so you don't accept to measure every cutting.

Stride five

Adhere the Outset Two 1x3s

Put the first two 1x3s (the top and bottom pieces) in place and attach them to the box you've built using glue and brad nails. If the edges of the 1x3s are rough, sand them before installing.

Footstep vi

Space & Spike the Rest of the 1x3s

Put the pegboard spacer in place confronting the 1x3s yous've simply installed, so attach the next pair of 1x3s (top and bottom), making sure the pegboard isn't too tightly wedged in place. Your outer box volition be slightly wobbly and not rigid yet, so use a foursquare to make sure the box isn't skewed. Continue in this manner until you lot've secured all of the 1x3s.

Step 7

Spike the Dorsum Piece

The remaining 24-in. x 24-in. piece of 1/2-in. plywood is to be used as the back piece. Fasten it with glue and brad nails. This will foursquare up the box and make the assembly rigid.

That'southward it, your sliding pegboard storage system is complete. At present yous tin can fill up both sides of each slice of pegboard with hand tools and other small workshop necessities.

Originally Published: February 05, 2022

How To Build A Rolling Set Wall,

Source: https://www.familyhandyman.com/project/saturday-morning-workshop-how-to-build-sliding-pegboard-storage/

Posted by: bradleygony1994.blogspot.com

0 Response to "How To Build A Rolling Set Wall"

Post a Comment